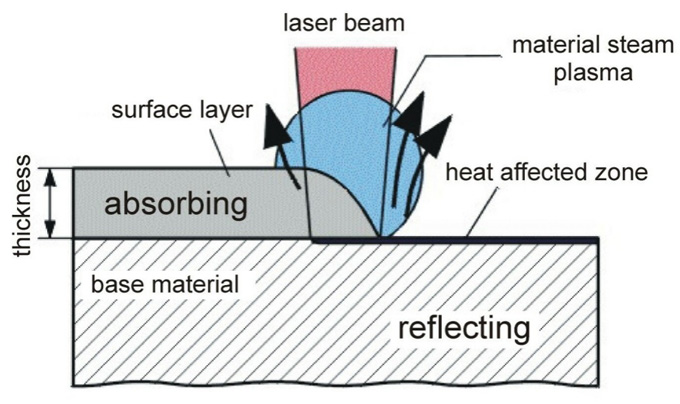

We must first understand the principle of laser cleaning.

The essence of laser cleaning is actually the complex physical and chemical interaction between the laser and the dirt layer, that is, through continuous or pulsed laser laser to overcome the bonding force between the dirt and the surface of the substrate, the dirt is separated from the surface of the substrate to achieve the purpose of cleaning.

The continuous or pulsed laser with high brightness and good directionality is formed by optical focusing and spot shaping to form a laser beam with a specific spot shape and energy distribution, and irradiate it to the location of the contaminated material that needs to be cleaned, and the contaminant material attached to it After absorbing laser energy, a series of complex physical and chemical processes such as vibration, melting, burning, and even gasification will occur, and finally the pollutants will be separated from the surface of the material without damaging the material itself. Even if the laser acts on the cleaned surface, most of it is reflected off and will not cause damage to the substrate.

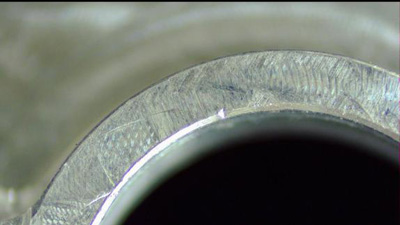

In principle, laser cleaning will not cause damage to the substrate. In actual operation, on the premise of achieving the ideal cleaning effect, will it cause damage to the substrate?

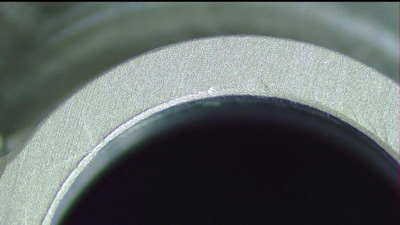

Suzhou Usiland surface laser cleaning test:(The left side is the uncleaned metal surface observed under the microscope, and the right side is the metal surface after laser cleaning)

Suzhou Usiland company has been developing and manufacturing high-quality laser cleaning equipment with a professional attitude, ranging from point-type laser cleaning machines, handheld laser cleaning machines, portable laser cleaning equipment to automated tire mold cleaning equipment and other more types of products. Aslan expands the scope of application of laser cleaning through a wealth of product categories to fully meet your various cleaning needs.

To provide you with the best cleaning solution, please contact Usiland company at: julie.zhou@usiland.com or Tel: +86 156 0154 6872